A physicist with a PhD in engineering and a passion for molecular biology, immunology, bioengineering, 3D printing and pulling things apart to see how they work – it’s difficult to categorise Dr Mazher Mohammed, but “ideas man” might just about cover it.

The inside of Dr Mazher Mohammed’s head is a busy place. He sees potential research projects everywhere, from plastic waste in the rubbish bin to investigating the acoustic properties of 3D printed musical instruments.

There is much laughter during an hour spent with the ebullient Yorkshireman, who runs on little sleep and lots of coffee, but Dr Mohammed is serious about his research and leaving the world a better place than he found it.

Dr Mohammed’s story is the third in Invenio’s series of profiles showcasing the people behind Deakin’s research and uncovering what drives them to make a difference to the world.

From medical breakthroughs, to developing world-first technology, to discovering new ways to help protect the environment, to building understanding between different cultures, Deakin’s researchers are creating innovative solutions to real-life issues facing our world.

Every one of them has a story to tell, and each month we’ll bring you that story in their own words.

Who is Dr Mazher ‘Iqy’ Mohammed?

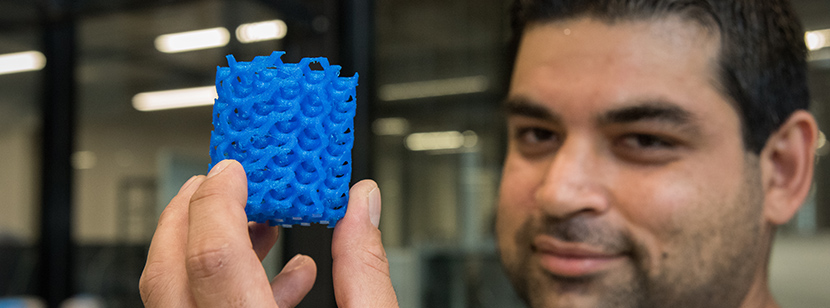

A Research Fellow (Advanced Design – Engineering) with the School of Engineering, Dr Mohammed has been involved in some impressive biomedical advancements in his almost three years at Deakin, including the development of a prosthetic ear and 3D printed jaw replacement, and a unique, crowd-funded project for delivering 3D printed plumbing solutions in the Solomon Islands using waste plastic.

After completing a Masters in Physics at University of Edinburgh, Dr Mohammed undertook a doctorate in engineering, known in the UK as an EngD, at Strathclyde University in Glasgow, and found his niche in engineering biomedical devices.

The “limitless opportunities” of 3D printing, and the opportunity to work with internationally renowned 3D printing pioneer Professor Ian Gibson, drew him to Deakin, where he last year won the Vice-Chancellor’s Award for “Advancements in 3D Printing Technologies”.

He has also featured on Network 10’s children’s science show “Scope,” taking Deakin’s biomed and 3D printing research to a wider audience:

In his own words…

How did you get from physics to bioengineering and 3D printing?

I really want to do research that results in something useable in the real world. When I did my physics degree, it was cool, but very esoteric. You never really got to see the fruits of your labour applied in a real setting. My course was also very theoretical, and I discovered I was more of an experimental physicist. At the same time, my Dad got osteoarthritis in his knee and needed a knee replacement. I thought, is there anything I can do with the work I’m doing which might be able to help in that space? Then my Mum, who has now passed away, got cancer. I felt that doing physics was all great – we could make particle accelerators and figure out the fundamentals of the universe – but how could that be applied to help people here and now?

So it made sense to explore something more medical, because I was always torn between physics and medicine. I thought maybe there was a way to apply my physics knowledge in the medical sphere, and bioengineering and medical devices seemed like the ideal opportunity.

The EngD in bioengineering medical devices began with a year of short courses that included biology, anatomy, bioelectronics and medical devices, as well as IT and copyright. My PhD project was to develop a point-of-care device that could be used to analyse a person’s genetic structure and tailor their medication to their genetic profile.

To achieve that, I needed an understanding of molecular biology and an understanding of manufacturing and optics and physics and signal processing. It was the pinnacle of multi-disciplinary research. It was mind-blowing how the subjects came together in one to enable the creation of the device, and it wouldn’t happen unless you had an intimate understanding of how DNA works, so it was really cool for me to sink my teeth into something completely different.

3D printing was a tool I could use to add to the repertoire. I think the opportunities to be had with 3D printing are almost limitless.

I call what I do application engineering with an emphasis on the life science/engineering interface – I think it should be a new category of engineering, if you can find the right brand for it. Biology, chemistry, material science, micro engineering, 3D printing, all those things feed into this one subject, really.

What brought you from the UK to Australia?

My wife is originally from the North of England as well, but she has lived in Australia for a long time and works with CSIRO on bio-sensing technology and microfluidics. We met at a conference in Barcelona and then I visited her here in 2012 and we got engaged. At the end of that same trip, we also found out we were expecting a baby, so my transition to Australia happened much quicker than expected.

I applied for jobs here, but I didn’t have a work visa and the opportunities in my field were pretty sparse. I wasn’t going to miss the birth of my daughter for anything, or her early years, so in the end I just packed in my job and came over on a temporary visa. I was a stay-at-home parent for the best part of two years and just kept my nose to the ground in terms of work opportunities.

I originally came to Deakin to work on microfluidics in the Centre for Regional and Rural Futures (CeRRF) with Professor Stephen Haswell, Chair of Microfluidics and Sensors. Then I saw a job advertised by Professor Ian Gibson in the School of Engineering that was specifically for medical device technology and thought it was a perfect match for my skillset.

What do you consider your greatest scientific achievement so far?

Definitely the 3D printed prosthetic ear [that last year allowed an Australian woman who lost her left ear in a car crash 55 years ago, when she was only 15, to receive a new ear] and working with the team who developed a 3D printed prosthetic jaw for a man in India, who can now smile and eat normally.

Is making a difference what motivates you most?

I had a conversation with my brother, who is a barrister, a long time ago when he suggested it might be time for me to think about doing something with more financial security than being a researcher, but I don’t see it like that.

My target was to help one person, and if I managed that, then another ten and another ten and keep on going. So I saw the prosthetic ear as helping one person, and the prosthetic jaw as helping someone else and the Solomon Island’s project as one where I could hit that ten and go straight to 100! There are opportunities for the biomed and environmental work we’re doing to transform the lives of so many people.

So making a difference has always been my motivation, but it’s been strengthened since having a child. I want to leave the world a better place than I found it, in whatever way is possible. I think there is a balance where the research and other things you do for a living can simultaneously be for social good.

Is this what you thought you would be doing when you grew up?

It’s almost exactly what I wanted to do. I have dreamed of being a scientist since I was about six.

At my core, I think I’m a true geek – I don’t see this as work, I see that I get paid to do my hobby. Basically, if I wasn’t doing this as my job I would still be interested in it anyway. I would buy my own 3D printer and have my own electronics set up; in fact my garage is a total mess of a workshop with all different sorts of projects going on. I just like fiddling around with things, dismantling things and putting them back together and improving them (as I see it), or breaking them, which is what usually happens!

But if I wasn’t doing this, I would be a professional mountain bike rider. Unfortunately, I’m not that good at it, but I love it with a passion.

What do you when you’re not at Deakin?

I love heavy metal music and jazz and I’ve recently taken up playing the drums and guitar again after a five-year hiatus. I was at a 3D printing conference in Austin, Texas and I met a Professor who 3D prints guitars and drums. He brought an entire ensemble with him to the conference and said, ‘have a go of the drums.’ So I did, and I just got the bug again.

In fact, it gave me an idea for a research project to investigate the acoustic properties of the 3D printed scaffolds we produce. I’ve found there’s a whole wealth of applications using 3D printing apart from biomed if you think about it, everything from product prototyping, lightweighting parts and even turning rubbish into community-enabling components!

Published by Deakin Research on 26 October 2017