Deakin researchers are engineering the next generation of wearable technologies, developing innovative clothing fibres with unique properties.

Scientists from Deakin University’s Institute for Frontier Materials (IFM) are creating fibres that could one day turn our clothes into chargers for electronic devices or allow them to keep track of our movements.

Clothes with charge

Wearable, flexible power sources are one step closer after IFM scientists created a fibre that stores charges between microscopic layers.

Dr Shayan Seyedin, a Research Fellow at IFM, spent three years working on ways to process energy-storing sheets of ‘MXene’ – a nanoscopic material made of carbon and titanium – into knittable fibres.

The result is a new class of fibre supercapacitors with potential for creating flexible power sources for miniaturised electronic gadgets and wearable technologies.

Working at a scale about 50,000 times thinner than a human hair, Dr Seyedin combined sheets of MXene with a small amount of ‘spinnable’ graphene, resulting in a fibre with ‘amazing energy properties’.

Watch as Dr Seyedin explains more about the MXene research:

Dr Seyedin said MXene, which was originally discovered in 2011 at Drexel University in the US, is typically not spinnable directly due to being made out of small sheets rather than interlocking polymers.

However, Dr Seyedin worked out a way to integrate MXene with graphene sheets, which wrinkled together into a strand of high-tech fibre that can be knitted into a fabric.

Dr Seyedin said the development showed MXene fibres could offer a wearable alternative to bulky batteries and portable chargers.

[testimonial_text]These results show that MXene is an excellent candidate for the development of fibre-shaped devices that potentially include supercapacitors, batteries, sensors, and other integrated fibre devices, all of which are becoming critical in meeting the demands of wearable and miniaturised electronics. We hope to transform the small fibres into actual wearable articles of clothing – whether that’s pants pockets, wristbands or shirt patches that are capable of storing energy and charging devices.[/testimonial_text]

[testimonial_picture name=”Dr Shayan Seyedin” details=”IFM Research Fellow”]

[/testimonial_picture]

[/testimonial_picture]The research team is now investigating how to produce the fibres in larger quantities and improve their performance and flexibility before testing them in real life applications.

‘At the moment we’re working on a small-scale device prototype which consists of fibres that are about two to three centimetres long. This small device is capable of charging electronic devices that don’t require much power, like smart watches and Fitbits,’ Dr Seyedin said.

‘Once we’re able to produce more of the fibres we can make larger patches that can potentially provide more energy.

‘What we’re working towards is an even more flexible option that can also be washed and produced at a large enough scale to cover areas such as the inner lining of a pants pocket.’

The project was funded by the Australian Research Council (ARC) through team leader Associate Professor Joselito Razal’s Future Fellowship and Discovery Project, the ARC Research Hub for Future Fibres, and by Deakin through Dr Seyedin’s Alfred Deakin Postdoctoral Research Fellowship.

Dr Seyedin recently received an Australian Government Endeavour Research Fellowship that will allow him to spend six months during 2018 working with the Drexel University team who discovered MXene, led by Professor Yury Gogotsi. He hopes the collaboration, which began last year, will contribute to the development of improved MXene fibres, with a PhD student from Drexel also arriving this year to work with the IFM team on MXene-related projects.

Read more: ‘Knittable energy storing fibre with high volumetric performance made from predominantly MXene nanosheets,’ co-authored by Dr Seyedin and Associate Professor Razal in ‘Journal of Materials Chemistry A’.

Clothes with sense

Dr Seyedin’s research into conductive fibres has also led to the creation of strain sensing textile fibres that could be used to create clothing that keeps track of its wearer’s movements, such as compression garments that monitor professional athletes during competition, or allows patients to track and compile data while undergoing physical rehabilitation.

The devices could also be applied to virtual and augmented reality technology, providing more thorough feedback and accurate movement within VR games and simulations.

‘Strain sensing textiles have particular relevance in the development of smart devices for health, sports, and soft robotics,’ Dr Seyedin said.

‘These wearable devices can convert a wide range of body movements into electrical signals, making it possible to track and record physical activities such as those involved in fitness and health monitoring, improving exercise efficiency, injury prevention and rehabilitation.’

Most effectively applied to joints with a high range of movement such as knee, elbow and finger joints, Dr Seyedin’s knitted textile prototypes rely on conductive elastic fibres that stretch and relax during movement.

As the resistance levels change, this information is sent to a computer monitor using a wireless transmitter chip, where it can then be recorded and used to provide feedback on body movement and biomechanics.

Dr Seyedin said this was the first time such technology had been scaled up to wearable levels, using standard industry processing and commercially available products to keep it affordable and accessible.

‘To date, there has been limited success in this area,’ he said. ‘The development of strain sensing textiles that can be worn directly – without the need for a supporting frame, substrate, or an additional clothing item – required significant advances in conductive fibre processing.’

Dr Seyedin said the ultimate goal was to combine the strain sensing and MXene projects.

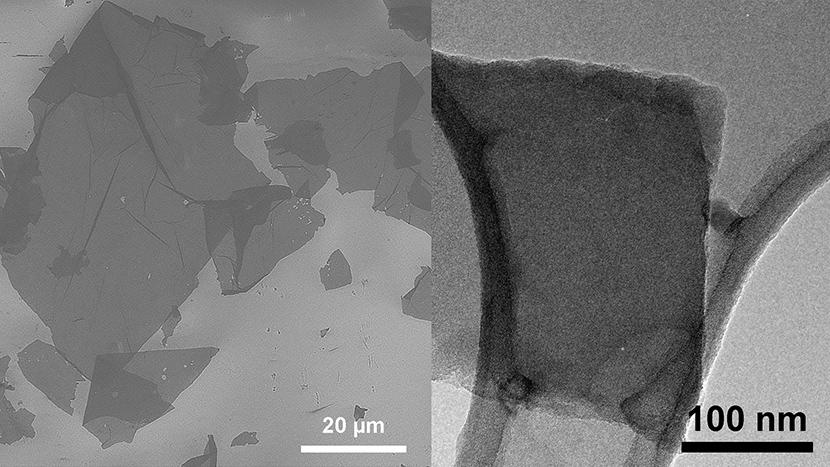

Graphene Nanosheets (left) compared to MXene Nanosheets (right)

‘Textiles are integral to the clothes we wear for comfort and for fashion, and making them into intelligent input/output devices provides a new opportunity in extending their function beyond the traditional use,’ he said.

‘There are sensors out there that measure small changes and pressure, but the fabric we have developed measures large movements and strains of up to 200 per cent, and is wearable on its own without the need for bulky or invasive supports.

‘What we’ve demonstrated is an entirely new concept with the material that we developed specifically for body monitoring applications.’

The project was funded by the Australian Research Council (ARC) through Associate Professor Razal’s Future Fellowship and Discovery Project, the ARC Research Hub for Future Fibres, and by Deakin through Dr Seyedin’s Alfred Deakin Postdoctoral Research Fellowship.

The research is set is set to be published in the June 2018 edition of ‘Applied Materials Today’.

Read more: ‘Continuous production of stretchable conductive multifilaments in kilometer scale enables facile knitting of wearable strain sensing textiles,’ co-authored by Dr Seyedin, Associate Professor Razal, Dr Sepehr Moradi and Dr Charanpreet Singh.

Published by Deakin Research on 26 April 2018