Deakin scientists have used cutting-edge nanomaterials to create a ‘molecular sieve’ that can be used in households, as well as in industries that need to decontaminate water used in their manufacturing processes.

Filters made using 2D nanomaterials have been an extraordinary advance for separating liquids, gases and ions. The downside is that they have limited permeability and are not used for watery or organic solvents. While increasing thickness can enhance their performance, it also increases manufacturing costs and decreases effectiveness.

However, a new filter created by researchers from Deakin University’s Institute for Frontier Materials (IFM) allows for small molecules to pass through while blocking larger ones because of the material’s atomic thickness and controllable dimensions.

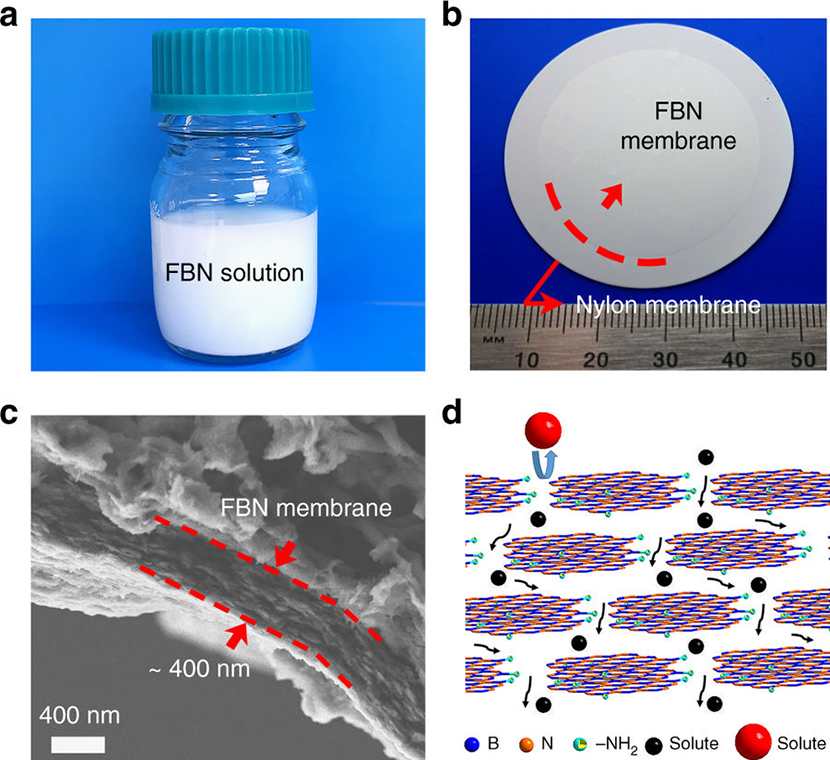

The researchers made the filter with layered flakes of hexagon-shaped chemical compound boron nitride, creating a stable and highly-resistant membrane that can filter and block out more than 99 per cent of nanoparticles.

Preparation of the functionalized boron nitride membrane and solute separation mechanism. a A photograph of the prepared FBN dispersion in water. b A photograph of the prepared FBN on a commercial nylon membrane; the edge of the FBN membrane is shown with a red dotted line. c The cross-sectional SEM image of a FBN-0.4 membrane. d Illustration of the solute separation mechanism

IFM Senior Research Fellow Dr Weiwei Lei explained that the filter features a nanochannel network to separate molecules and is highly permeable because the 2D nanomaterials used to create it generate random nanochannels when stacked together during assembly.

Dr Lei said the membrane could be used to provide clean drinking water, while also being effective at purifying organic solvents such as acetone and alcohol.

“The separation and recovery of organic solvents is a global problem for chemical and pharmaceutical companies, accounting for 40 per cent to 70 per cent of operating costs,” Dr Lei said.

[testimonial_text]Any new efficient separation process or materials will minimise the cost and consumption of energy, which is in high demand now.[/testimonial_text]

[testimonial_picture name=”Dr Weiwei Lei” details=”Deakin University’s Institute for Frontier Materials (IFM)”]

[/testimonial_picture]

[/testimonial_picture]Dr Lei said it was the first time chemically stable boron nitride had been used to create a functional membrane, and it was much more effective than commercial filter membranes and others based on two-dimensional nanomaterials.

As boron nitride is normally hydrophobic, it’s difficult to make it water soluble in order to synthesise its membrane.

In a world first, Dr Lei and his team modified the surface of boron nitride to make it hydrophilic, which allowed them to use the solution to create the filter.

“Our new membrane has an adjustable thickness and high durability – and unlike commercial membranes currently on the market it is stable under harsh conditions, such as in acidic and basic solutions,” Dr Lei said.

“It exhibits unprecedented transport performance for organic solvents and water, over 1000 times higher than that of commercial ultrafiltration membrane.”

The plasma and 2D materials team at IFM is an internationally recognised leader in plasma and 2D nanomaterials research. Previous breakthroughs from Dr Lei and his collaborators have included a boron nitride nanosheet sponge capable of absorbing oil from water, which has been used to treat oil spills.

Read more:

- “Functionalised boron nitride membranes with ultrafast solvent transport performance for molecular separation” Nature Communications

Published by Deakin Research on 28 May 2018